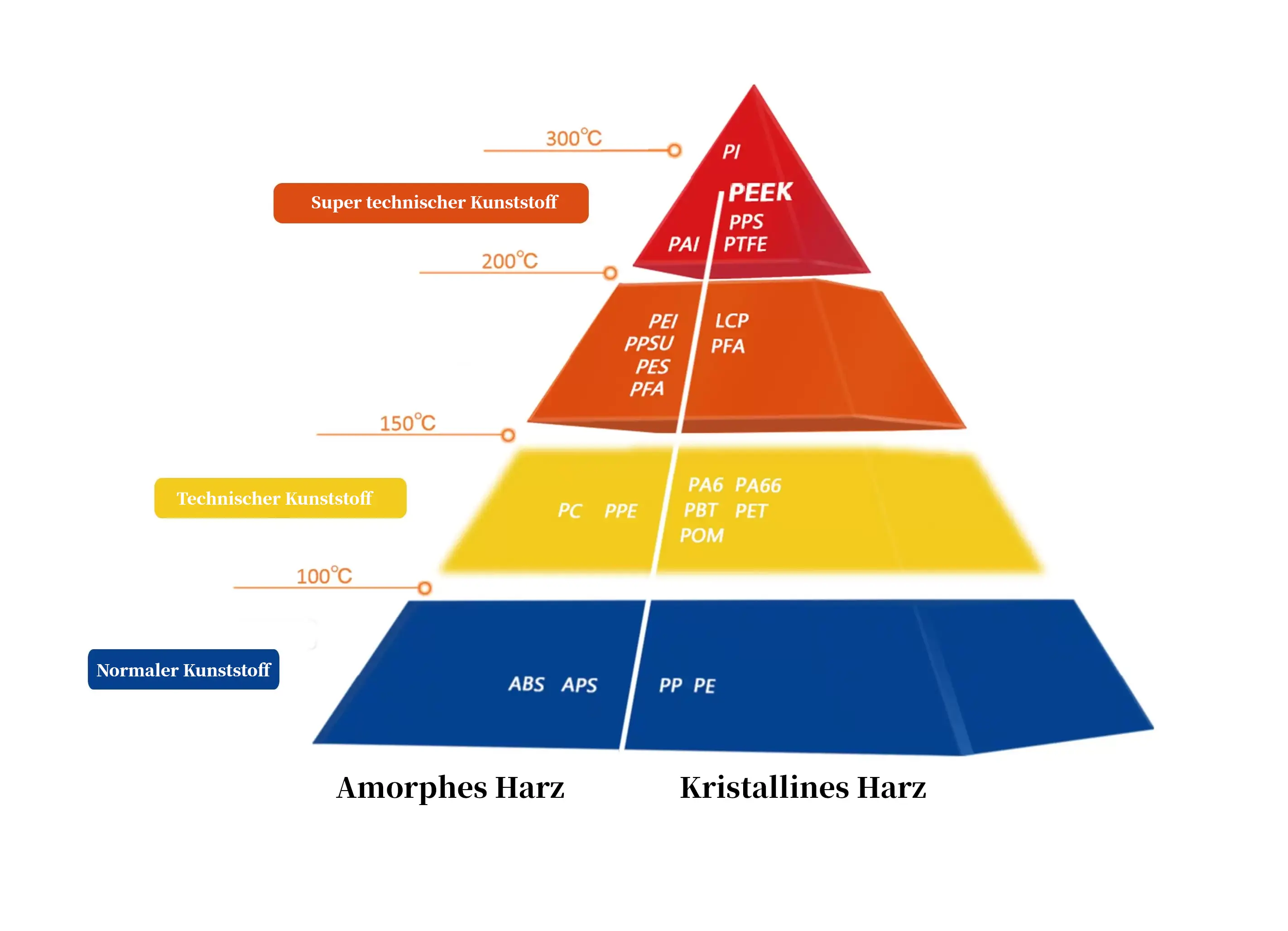

PEEK polymer petroleum & petrochemical industry solutions can improve the production safety and stability of equipment in high temperature and corrosive environments to improve production efficiency.

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

Double the Service Life

Double the Service Life Self-lubricating

Self-lubricating

PEEK-Dichtungen

Effektive Abdichtung bedeutet oft sichere, langlebige und effiziente Produktionsabläufe, was weniger Ausfallzeiten und geringere Kosten bedeutet. PEEK-Sicherungsringe werden in der Energieindustrie wegen ihrer hervorragenden Zuverlässigkeit bevorzugt. PEEK-Dichtungslösungen sind bewährte und zuverlässige Lösungen, die die Lebensdauer der Geräte verlängern und die Rückgewinnungsraten in korrosiven Umgebungen bei hohen Temperaturen und hohem Druck verbessern.

In der Umgebung von Meerwasser, Kohlenwasserstoffen und 100% Schwefelwasserstoff erreicht die Festigkeitsretentionsrate 100% nach einer hohen Temperatur von 175° C für 1000 Stunden.

Verdoppeln Sie den Kompressionswiderstand von PTFE, erhöhen Sie den Kriechwiderstand um 300-mal und erhöhen Sie den Druck-Kriechwiderstand von PTFE um 18-mal.

Ersetzen Sie die Metallfeder, um das Risiko durch den Verschleiß der Dichtung und den Kontakt mit der Brunnenwand (energieabsorbierende Feder) zu verringern.

Kompressor Teile

Angesichts der hohen Anforderungen der Industrie an eine längere Lebensdauer und weniger Ausfallzeiten bieten PEEK-Lösungen Kompressorteilen eine einzigartige Kombination aus Leistung. Reduzierte Wartungskosten und Materialgewicht, ausgezeichnete Integrität, Beständigkeit gegen aggressive Chemikalien und Flüssigkeiten sowie Langlebigkeit in mechanischen Geräten und verschleißgefährdeten Umgebungen.

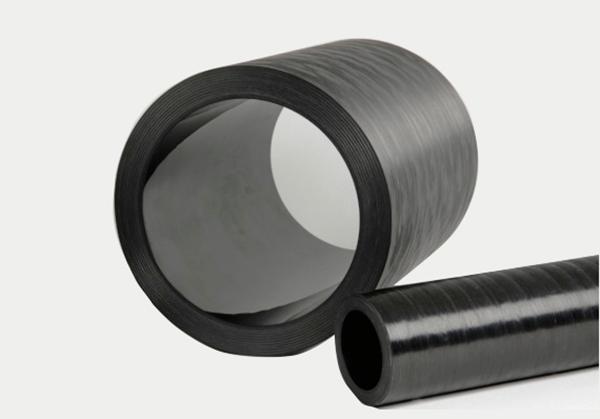

Continuous Carbon Fiber CF/PEEK Composite Rohr

PEEK wird aufgrund seiner einzigartigen Kombination aus chemischer Beständigkeit, elektrischen Eigenschaften, Abriebfestigkeit, Hydrolysebeständigkeit und hoher Temperaturbeständigkeit zunehmend in vielen Öl- und Gasindustrieanwendungen eingesetzt. Produktion Da die Betriebssysteme von Öl- und Gasreservoirs weiter wachsen, erfordern neue Tiefseeplattformen neue Lösungen, um zuverlässige Leistung in Umgebungen mit höheren Temperaturen, höheren Drücken und extremen Tiefen zu liefern. Zuverlässigkeit hat höchste Priorität wegen der hohen Investitions-, Interventionskosten und Ertragsverluste, die höhere Anforderungen an das Material stellen.

Anwendung in der elektrischen Tauchpumpe ESP

ESP-Technologie erfreut sich rasant wachsender Beliebtheit und wird in nahezu jedem Einsatzgebiet der Welt eingesetzt. PEEK-Isolierring kann der hohen Temperatur standhalten, die durch die Spulenheizung verursacht wird, die durch den ESP-Tauchmotor lange Zeit Arbeit erzeugt wird, und es bietet eine gute Isolierwirkung bei ausreichender mechanischer Festigkeit.

Ausgezeichnete Hochtemperaturbeständigkeit, ausgezeichnete Isolierung, Isolierung und mechanische Festigkeit auch bei 250°C.

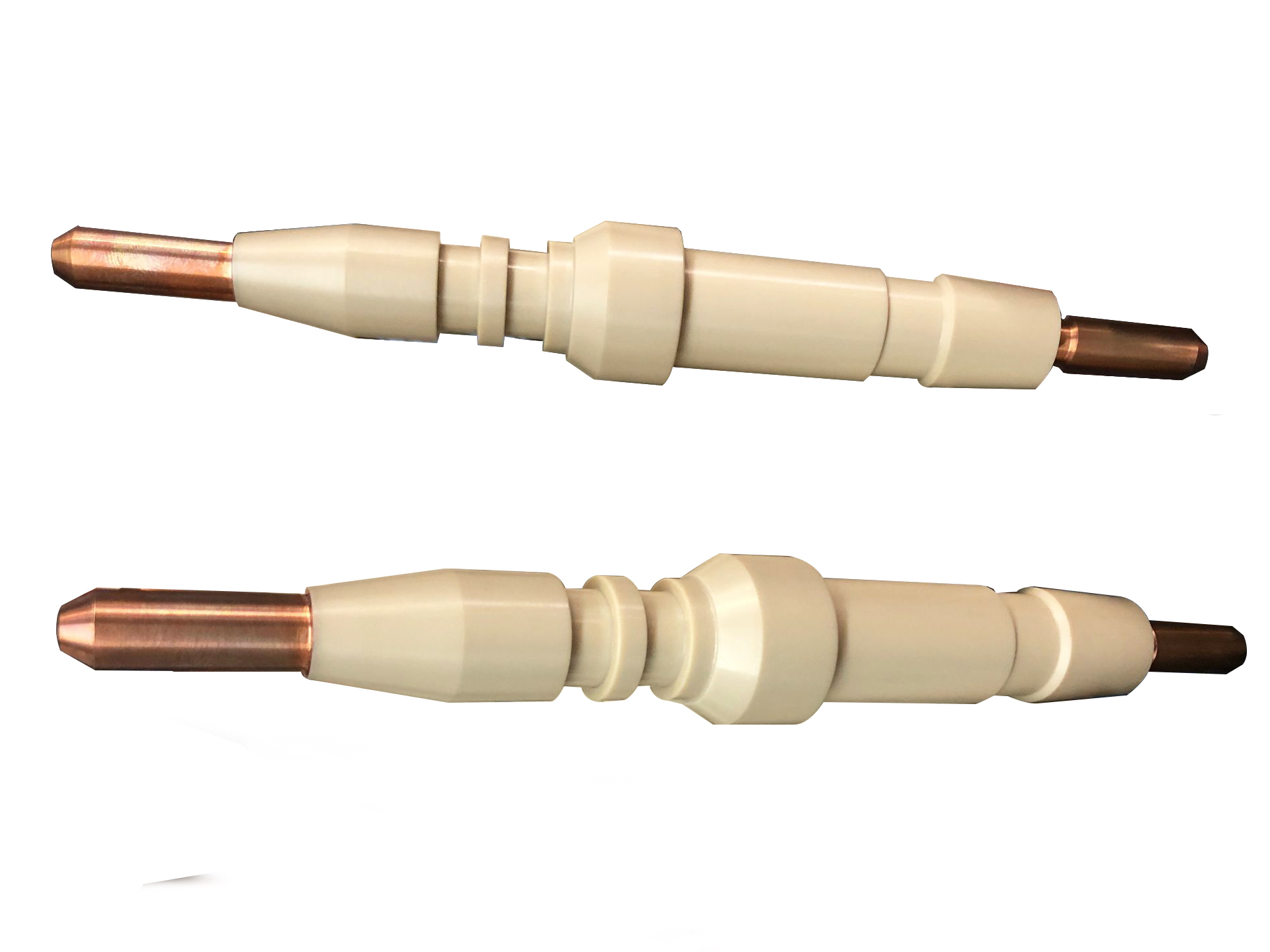

PEEK Well Logging Part

PEEK bietet die chemischen und isolierenden Eigenschaften, die erforderlich sind, um Signale bei hohen Temperaturen zu schützen, und bietet die Möglichkeit, nahtlose Verbindungen herzustellen, die leitfähige Stifte vollständig isolieren und ihre Leistung unter härtesten Bedingungen gewährleisten. Die hohe Reinheit und Festigkeit von PEEK ermöglichen die Konstruktion dünnerer dünnwandiger Querschnitte in kompakteren Steckverbindern und ermöglichen eine hervorragende Leistung auch bei engen Platzverhältnissen. Beständig gegen typische Öl- und Gasindustrieflüssigkeiten.