Poly (ether ether ketone)(PEEK) is a linear polymer whose main chain is composed of Aryl, ketone and ether bonds. PEEK has a large number of benzene rings in its molecular chain, so its heat resistance can match that of polyimide, while two ether chains and a renegade group provide the material with flexibility and excellent workmanship.The structure is as follows:

High Temperature Performance

High Temperature Performance High Wear Resistance

High Wear Resistance Mechanical Strength and Dimensional Stability

Mechanical Strength and Dimensional Stability Resistance to Harsh Chemicals

Resistance to Harsh Chemicals High Electrical Integrity

High Electrical Integrity High Purity & Bio-inert

High Purity & Bio-inert![]()

Aerospace

![]()

Food

![]()

Mechanics

![]()

Medicine

![]()

Oil and gas

![]()

Semiconductors

We started the PEEK polymerization project in 2014 and completed the pilot test in 2016. In 2018, Shandong Junhao HPP Co., Ltd. was officially established in Jining, Shandong Province, China, to carry out industrial production of PEEK polymerization, and finally in 2019, we complete the production of PEEK industrial chain.

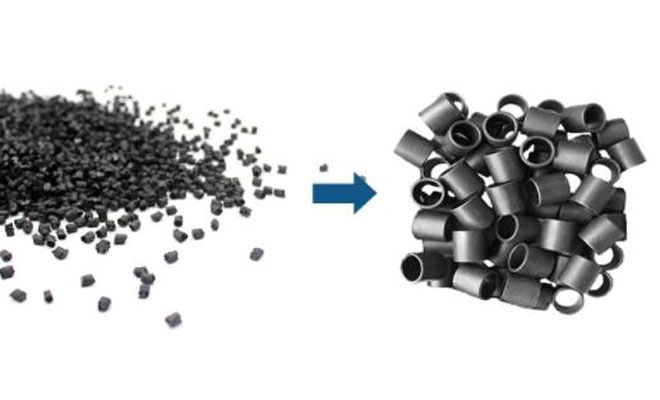

Blending modification is the most commonly used method for modifying PEEK materials. Typically, fibers, metal oxides, inorganic fillers, and high-molecular polymers (such as PTFE) can be added to the raw materials.The PEEK composite material prepared by this method can improve the defects of PEEK by using the composite effect, and improve the comprehensive properties of the material to a great extent.

The addition of PTFE, graphite and carbon fibre makes PEEK5600LF30 a bearing grade plastic. Its superior friction properties (low coefficient of friction, wear resistance, high peak pressure limit) make this grade an ideal material for friction applications. It is suitable for the manufacture of wear strips, friction discs and other products.

According to the liquidity, it can be subdivided into: PEEK3600LF30; PEEK5600LF30.PEEK3600GF30 is a high mobility PEEK particle.

| Item | Test Standard or Instrument | Unit | PEEK+30%(Carbon fiber+Graphite+PTFE) PEEK3600LF30 | PEEK+30%(Carbon fiber+Graphite+PTFE) PEEK5600LF30 |

|---|---|---|---|---|

| Tensile strength (23 ℃) | ISO-527 | MPa | 140 | 140 |

| Tensile modulus (23 ℃) | ISO-527 | GPa | 14 | 14 |

| Tensile elongation (23 ℃) | ISO-527 | % | 3.0 | 3.0 |

| Bending strength (23 ℃) | ISO 178 | MPa | 210 | 210 |

| Bending modulus (23 ℃) | ISO 178 | GPa | 11.5 | 11.5 |

| Compressive strength (23 ℃) | ISO 604 | MPa | 165 | 165 |

| LZOD notched impact strength | ISO 180/A | KJ/㎡ | 28 | 31 |

Most standard reciprocating screw injection moulding machines are capable of moulding unfilled and filled PEEK grades. Complex and intricate high performance components can be mass-produced without annealing or conventional machining. technical experts can assist with design and process variables such as machine design, barrel capacity, screw and mold design and gating.

PEEK thermoplastics can be used in extrusion processes and equipment including wire coating, profile extrusion, film, pipe, sheet and monofilament production. Unfilled and filled grades are readily extruded using conventional melt processing technology. Our highly experienced technical team can help define the machine design and address any processing challenges.

Compression moulded parts are generally more crystalline, have a higher modulus and tensile strength and are harder with a lower ductility. Glass and carbon fibres may be combined with PEEK for compression moulding. Our technical team recommends that our customers anneal parts with very thick sections to relieve stresses.