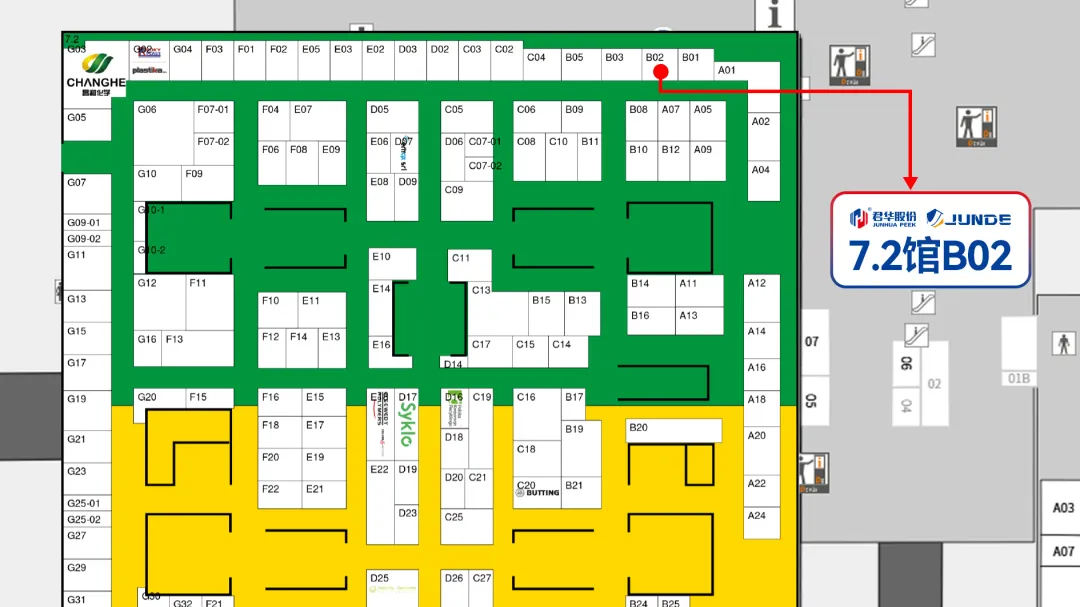

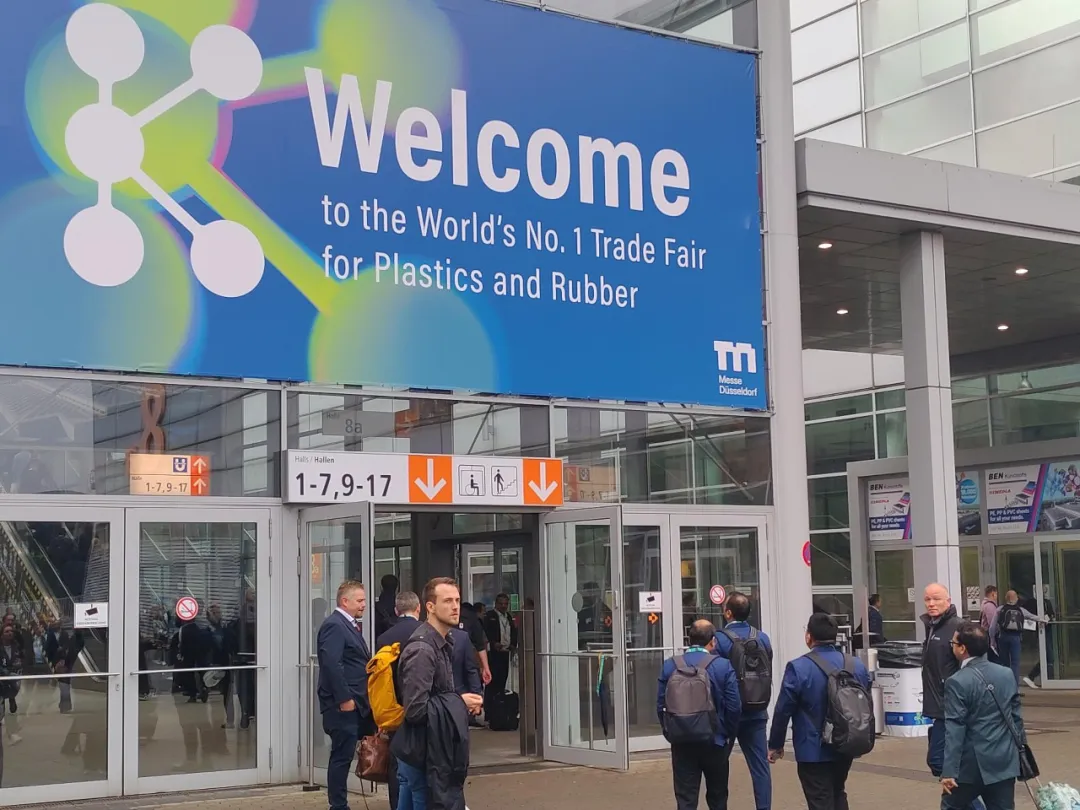

In the golden autumn of October, the triennial K Show grandly opened in Düsseldorf, Germany. As the world’s premier event for the plastics and rubber industry, the K Show has always been a vital platform for innovation and exchange within the industry. JunDe made a splendid appearance at booth B02 in Hall 7.2, showcasing a series of innovative products, including high-performance PEEK particles, profiles, and finished products. This marked the company’s fourth appearance on the international stage of the K Show since 2016.

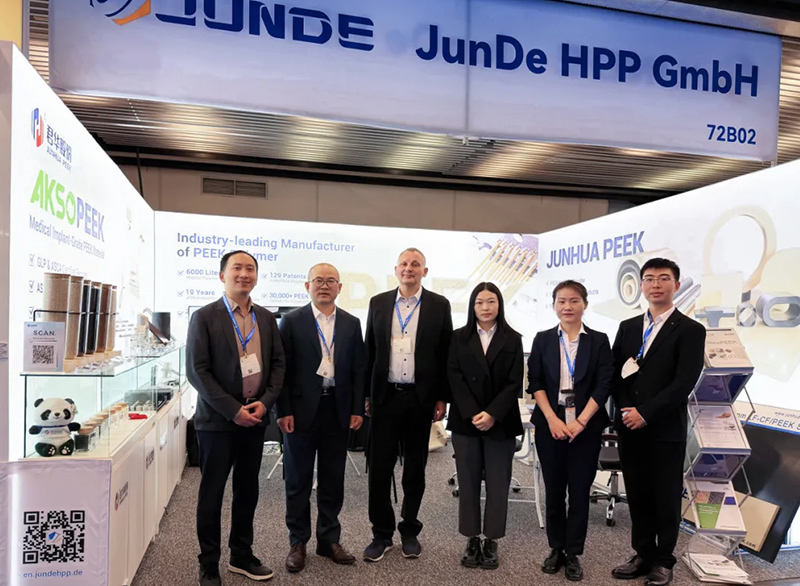

Although visitor numbers fell short of pre-show expectations due to the slowdown in global economic recovery and international geopolitical factors, the exhibition still attracted a global audience of professional visitors and industry elites. JunDe presented its expertise in resin raw materials, profile extrusion, equipment, and mold technology, demonstrating the company’s strength and innovation in the field of high-performance materials.

During the exhibition, the JunDe booth drew considerable attention from international customers and industry experts. The team engaged in in-depth discussions with partners from around the world on PEEK’s application development, performance characteristics, and potential opportunities for future collaboration.

JunDe Pharmaceutical’s independently developed AKSOPEEK® material, strictly adhering to the YY/T 0660-2008 standard, boasts ultra-high purity, excellent bioactivity, and exceptional biocompatibility. The material is available in a variety of forms, from raw material particles and profiles to implant-grade 3D printing filaments. Finished products, such as 3D-printed skull pieces, were on display, fully demonstrating its potential for application in orthopedic implants and high-end medical devices.

While retaining the excellent properties of the PEEK family, the low-melting-point DRDPEAK material achieves a significant breakthrough in processability. Its melting point is approximately 40°C lower than conventional PEEK. This lower molding temperature not only makes the processing more energy-efficient and efficient, but also offers greater design freedom and a wider range of process adaptability. It is particularly suitable for the manufacture of complex structures and precision parts, making it an ideal choice for additive manufacturing, composite materials, and welding processes.

High-performance winding sheaths and related products made from carbon fiber reinforced PEEK prepreg tapes through advanced winding molding technology are lightweight, ultra-high strength, and have excellent sealing properties, making them suitable for high-end industrial and aerospace fields.

It is worth noting that many European customers have shown great interest in purchasing PEEK pellets, planning to use them for independent injection molding; some customers also expressed interest in purchasing rods for their own processing.

At the same time, customers have put forward clear requirements and expectations for market access testing and certification, ESG and carbon footprint management. JunDe will actively plan and promote the construction of relevant systems in the future to better meet international market standards.

JunDe boasts a complete PEEK industry chain, independently completing everything from resin polymerization and profile extrusion to finished parts processing. The company currently holds 115 valid patents, and its products are widely used in high-tech fields such as aerospace, medical implants, electronics, and new energy. The company is committed to breaking the monopoly on foreign technology and achieving import substitution for key materials.

From October 8th to 15th, you are welcome to visit JunDe’s booth at the K Show in Düsseldorf (booth number: 72B02) to have face-to-face exchanges with JunDe’s professional team, jointly explore solutions, and work together to create new opportunities for industry development.