As a member of special engineering plastics, PEEK (Polyetheretherketone) is widely used in industrial production due to its light weight, high strength, wear resistance, corrosion resistance, high-temperature resistance, and other properties. Due to its good biocompatibility and an elastic modulus similar to human bone, it is known as a new generation of ideal orthopedic implant materials after titanium alloys.

PEEK Fatigue Properties

Fatigue refers to the phenomenon where materials, parts, and components experience local damage at certain points or areas under cyclic loading, leading to crack formation or crack propagation until complete fracture after a certain number of cycles. Fatigue performance refers to a material's ability to resist fatigue failure [1].

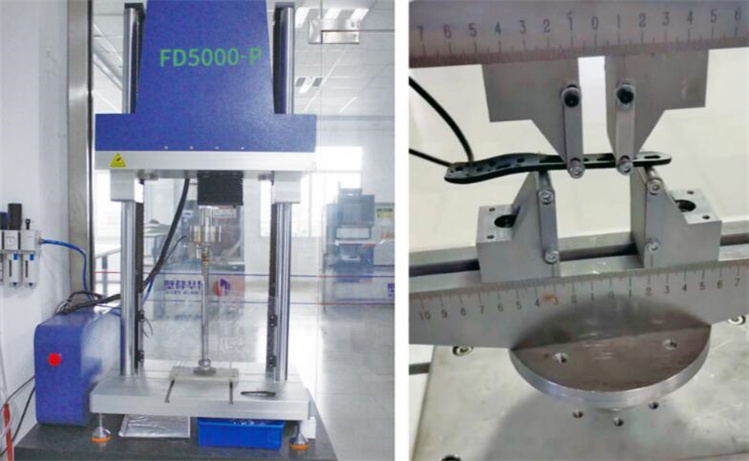

Let's talk about the fatigue properties of PEEK today. Using the test standard YY/T 1503 (ASTM F382), under a load of 800N, a frequency of 5Hz, and 1.2 million test cycles, the AKSOPEEK® LCF bone plate (4mm thickness) was tested. In the bending fatigue test, the performance is comparable to that of titanium alloys and better than pure titanium.

To further compare the fatigue resistance of AKSOPEEK® LCF and titanium alloys, we selected four groups of 2mm thick titanium alloys (Ti-6Al-4V) and AKSOPEEK® LCF splines for fatigue testing under a load of 382N. The AKSOPEEK® samples did not fail after 1 million cycles, while the titanium alloy samples failed due to fatigue at 73,000, 82,000, 79,000, and 92,000 cycles.

Using the test standard YY/T 0959 (ASTM F2077), under a load of 2000/4000N, a frequency of 5Hz, and 5 million test cycles, the AKSOPEEK® natural interbody cage (height 6.3mm) was tested for compression fatigue. No fatigue failure occurred. The static test before and after fatigue showed no decrease in strength, and the compressive yield of this cage type was only 12000N.

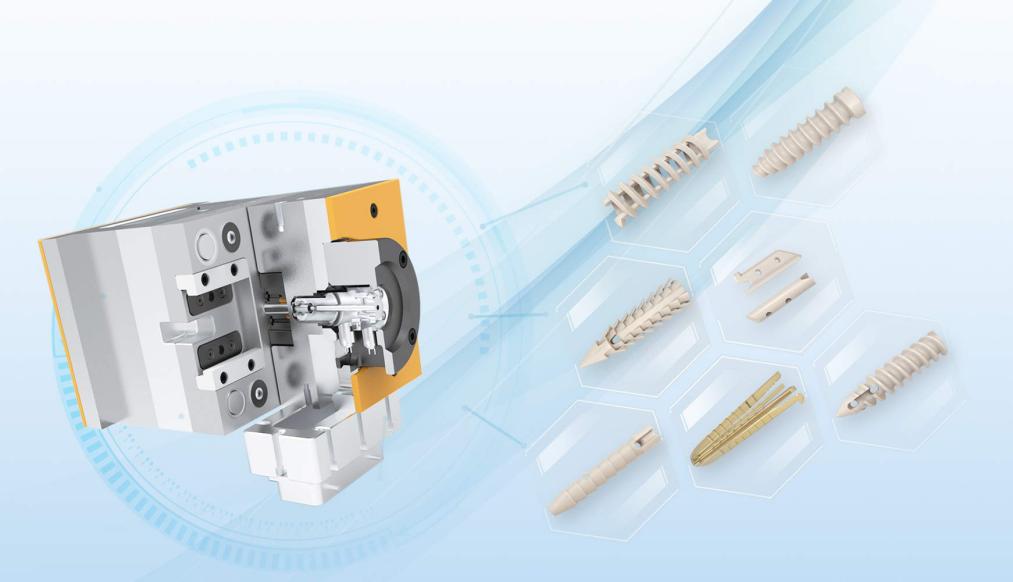

In-Depth Cultivation of Sports Medicine

(1) Years of experience in PEEK injection molding;

(2) Perfect sports medicine development process;

(3) Miniature injection molding machines of the same brand and model provide complete seamless switching with partners;

(4) The perfect after-sales service system has been recognized by major domestic medical institutions.

AKSOPEEK® Material Types

1) AKSOPEEK® Natural: Pure implantable PEEK material;

2) AKSOPEEK® HA: Hydroxyapatite improves the biocompatibility of implant-grade PEEK material;

3) AKSOPEEK® CF: Chopped carbon fiber implant-grade PEEK material;

4) AKSOPEEK® LCF: Continuous carbon fiber implant-grade PEEK material.