PPSU is a type of amorphous, high-performance thermoplastic. Compared to PEI and PEI, PPSU exhibits superior impact strength and chemical resistance. High-pressure steam sterilization tests have proven that PPSU has superior hydrolysis resistance to other amorphous plastics. In fact, PPSU can withstand millions of high-pressure steam sterilizations, making it a very good choice for medical applications.

Through high-pressure steam sterilization testing, PPSU has been proven to have superior hydrolysis resistance to other amorphous plastics. In fact, PPSU can withstand millions of high-pressure steam sterilizations, making it a very good choice for medical applications.

◆ High temperature resistance

◆ High hardness

◆ Good chemical compatibility

◆ Good impact resistance

◆ Good dimensional stability

◆ Good electrical insulation

◆ Good hydrolysis resistance

◆ Excellent resistance to high-energy radiation (γ-ray and X-ray)

◆ Good dielectric properties

| Typical values for undyed product at 23℃ | Test procedures | Unit | Data |

|---|---|---|---|

| Mechanical properties | |||

| Tensile strength | ISO 527-1/-2 | MPa | 70 |

| Zugmodul | ISO 527-1/-2 | MPa | 2270 |

| Train extension (yield) | ISO 527-1/-2 | % | 7.8 |

| Flexural strength | ISO 178 | MPa | 105 |

| Flexmodul | ISO 178 | MPa | 2400 |

| Kerbschlag Izod | ISO 180/A | KJ/㎡ | 68 |

| Thermal properties | |||

| HDT/A @1.8MPa heat deflection temperature | ISO 75-1/-2 | ℃ | 196 |

| DSC, 10℃/min glass transition temperature | ISO 11357-1/-2 | ℃ | 220 |

| 23℃,CLTE-Flow | ISO11359-1/-2 | E -6 /K | 55 |

| Flammability | |||

| 1.5mm Flame Rating@1.5mm Thickness | UL94 | Class | V-0 |

| Electrical properties | |||

| 100V Volumenwiderstand | I EC 60093 | Ohm | >1E13 |

| 100V surface resistance | I EC 60093 | Oh | >1E15 |

| Dielectric constant @100HZ @1MHZ | I EC 60250 | 3.8 3.7 | |

| Dissipationsfaktor @100HZ @1MHZ | I EC 60250 | E -4 | 15 86 |

| K20/K20, (60*60*1 mm3)Dielectric strength | I EC 60243-1 | KV/mm | 44 |

| CTI | I EC 60112 | 150 | |

| General properties and processability | |||

| density | ISO1183 | g/c㎡ | 1.29 |

| Moisture absorption, equilibrium 23℃/50% rh | ISO62 | % | 0.6 |

| Mold shrinkage (flow) | ISO 2577, 294-4 | % | 0.9 |

| Mold shrinkage (vertical) | ISO 2577, 294-4 | % | 1 |

| MFR @365℃/5kg | ISO 1133 | g/10min | 28-38 |

| Processing (Melt)Temp, Injection/Extrusion | ℃ | 350-390 | |

| Mold temperature, Injection/Extrusion | ℃ | 140-180 |

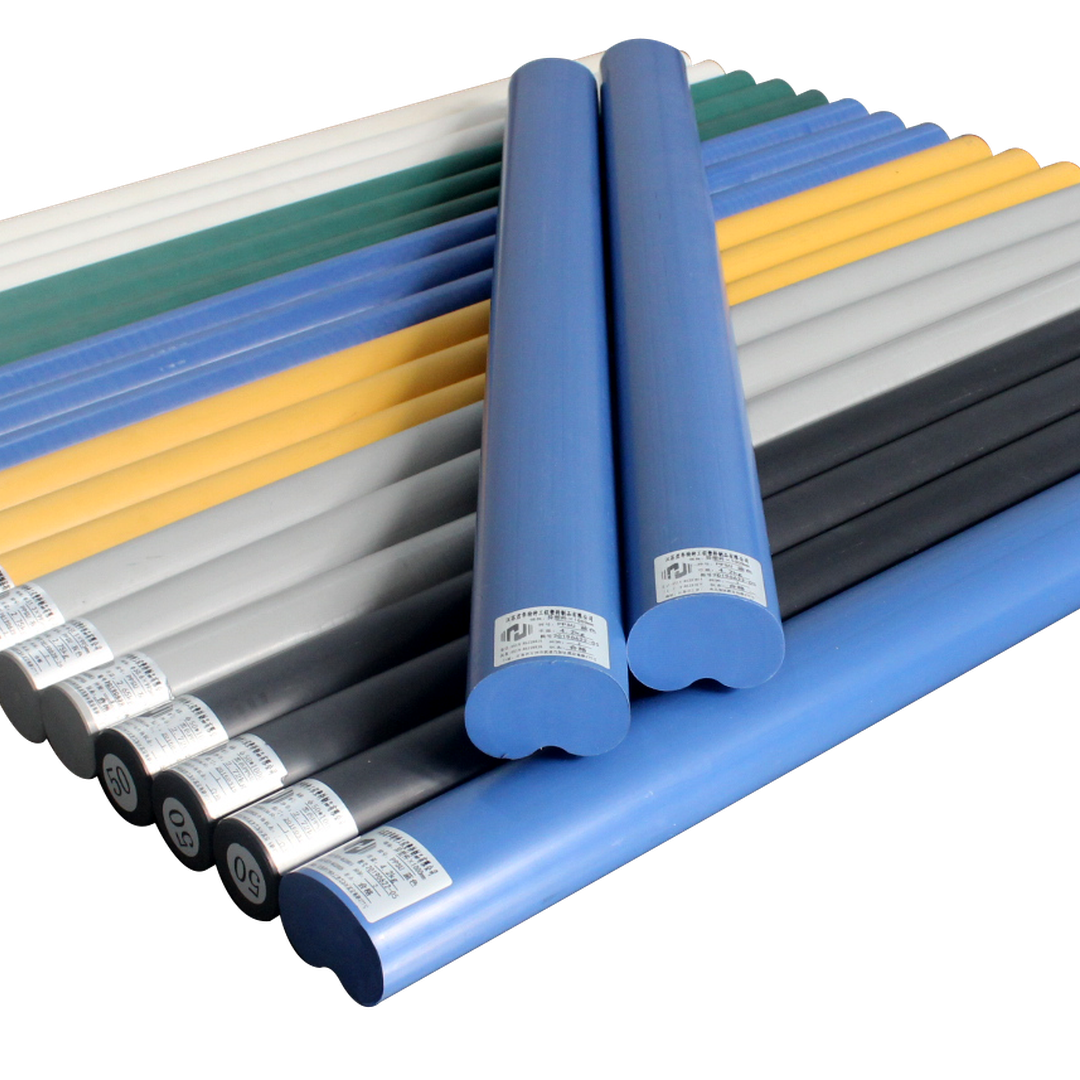

| Serial number | (mm) | Serial number | (mm) | Serial number | (mm) | Serial number | (mm) |

|---|---|---|---|---|---|---|---|

| 1 | 5 | 13 | 25 | 25 | 48 | 37 | 95 |

| 2 | 6 | 14 | 26 | 26 | 50 | 38 | 96.5 |

| 3 | 8 | 15 | 26.7 | 27 | 53 | 39 | 100 |

| 4 | 10 | 16 | 28 | 28 | 55 | 40 | 106 |

| 5 | 12 | 17 | 30 | 29 | 60 | 41 | 110 |

| 6 | 13 | 18 | 32 | 30 | 65 | 42 | 115 |

| 7 | 15 | 19 | 33 | 31 | 70 | 43 | 120 |

| 8 | 16 | 20 | 35 | 32 | 75 | 44 | 125 |

| 9 | 18 | 21 | 38 | 33 | 80 | 45 | 130 |

| 10 | 20 | 22 | 40 | 34 | 85 | 46 | 140 |

| 11 | 21 | 23 | 42 | 35 | 90 | 47 | 150 |

| 12 | 22 | 24 | 45 | 36 | 94 |

PPSU battery box

PPSU Spine Extension

PPSU puncture handle

Joint Head PPSU